Loading Port and Collision Protection OHIO

Due to the non-renewal of the permit for the existing propane loading port at Chemelot, a new port had to be built in the short term. The new location had stricter requirements from ROK 2.0 and had complex soil conditions that deviated from the standard calculation methods. As a result, Van Den Biggelaar and Sitech was looking for a reliable and flexible partner for design and engineering so that a permittable and feasible design could be delivered quickly.

Key facts about the project

- Sector

- Structural Hydraulic Engineering

- Location

- Stein, Limburg

- Contactor

- Sitech

- Project type

- Design Collision Protection

Our approach

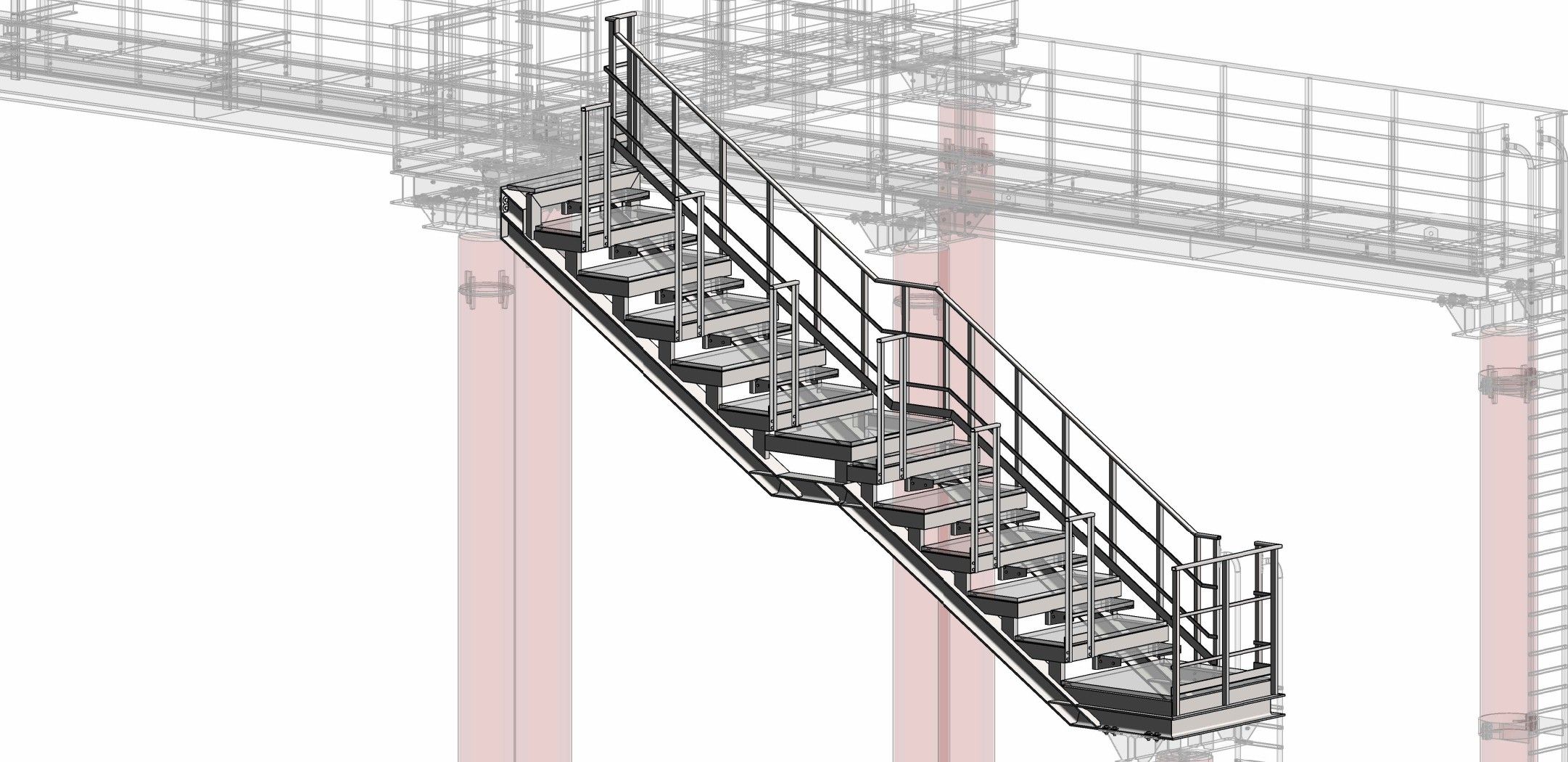

By going through the various design steps (VO, DO, UO) in a short time and actively maintaining contact with RWS to arrive at a permitted design within 9 months. Then we continued to arrive at a smooth implementation together. For this, many components were made in the workshop and only had to be welded together on location. The basis for this were the 3D models in Revit. This accelerated the implementation enormously, so that the whole thing was realized in about a year.

Methods and techniques

Where in most cases the geotechnical energy absorption is decisive, in this case the energy absorption of the structure itself was decisive due to the stiff Limburg soil. When this became clear, the transition was quickly made to the construction team and an automated calculation process was developed with which the energy absorption of a structure was optimized by means of SCIA.

Results to be proud of

- from program of requirements to final design

- 9 months

- less steel used

- 171 tons

- implementation completed

- within 1 year

- less C02 emissions

- 350 tons

Results and Advantages

Thanks to our swift, automated approach, we complete the entire design process in record time. Working with detailed 3D-models (Revit) makes the implementation smooth and safe – with minimal risks on site. In addition, smart design choices ensure a lower environmental impact and less use of materials such as steel.

Impact

Our approach guarantees continuity in the management and fast realization of complex projects. This is how a new loading port was completed before the old permits expired. The implementation was safe and efficient, resulting in 350 tons less CO2 emissions due to steel reduction.

Why BT Engineering?

We switch quickly between disciplines and combine automation with specialist knowledge. Our BIM modelers deliver safe, detailed designs in 3D and prevent errors through smart clash detection. This is how we arrive at the optimal design – faster, better and more sustainable.