Replacement of drinking water pipes

Smart pipe replacement under time pressure

Dunea and Heineken needed to replace outdated pipes along the busy Europaweg in Leiden. Due to the tight time frame for the reconstruction and the major traffic and economic impact, an efficient approach was crucial. The challenge: to renew the pipes within the tight schedule and meet all technical requirements — without delays or additional inconvenience.

Key facts of this project

- Sector

- Kabels & Leidingen

- Client

- Dunea

- Location

- Leiden, Europaweg

- Type of project

- Gesloten Front Boring (GFT)

Our approach

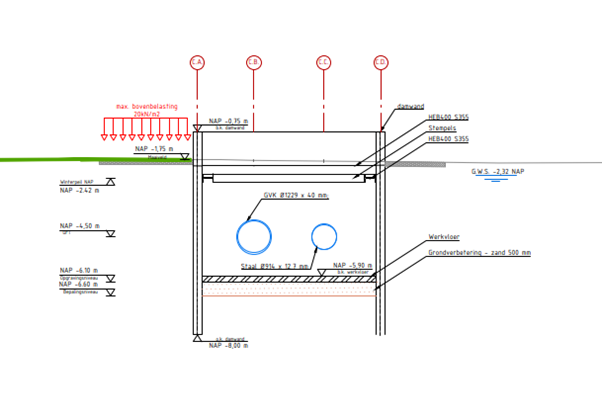

BT Engineering developed a smart and feasible design, taking implementation risks into account from the outset. We chose a Closed Front Boring (CFB) method, in which two construction pits are constructed to cross the pipeline without open excavation. This was necessary due to the technical complexity of the location, where various forces converged on a small surface area.

Success factor

The design takes into account risk factors such as the interaction between sheet piling and struts, the pressure load from the drilling machine, and the influence of high water pressure on the subsoil.

In addition, the integrated design minimizes environmental risks such as subsidence due to drainage and possible disruptions to surrounding infrastructure. Thanks to this approach, the contractor can carry out the project without delay and with minimal impact on traffic and the environment.

Results to be proud of

- supplied with drinking water

- 600.000 huishoudens

- concrete saved

- 100 m³

- Completion within the tight time frame

- 100%

- CO₂ saved

- 20 ton

Results & Benefits

BT Engineering delivered a solution that will ensure 600,000 households continue to have access to reliable drinking water in the future. Smart designs and risk management reduced material usage and transport movements. Rapid implementation with minimal traffic disruption also limited CO₂ emissions from stationary traffic.

Impact

A sustainable infrastructure guarantees safe drinking water for 600,000 households for decades to come. By saving 100 m³ of concrete, 20 tons of CO₂ were saved. The efficient execution ensured minimal impact on traffic and the environment.

Why BT Engineering?

We combine in-depth knowledge of implementation risks and complex technical designs with a sharp focus on practical applicability. We actively listen, contribute ideas, and deliver safe, sustainable solutions that contribute to a better future.